- PolyJet Legacy Printers

- Alaris30 V1

- Connex260

- Connex350/500

- Eden250

- Eden260

- Eden260V/VS

- Eden330

- Eden350

- Eden350V/500V

- J700 & J720 Dental

- J750/J735

- J750 Digital Anatomy

- Objet24/30 V2 Family

- Objet24/30 V3 Family

- Objet30 V5 Pro & Prime

- Objet260 Connex 1-2-3

- Objet260 Dental & Dental Selection

- Objet350/500 Connex 1-2-3

- Objet1000 Plus

- PolyJet Materials

- Agilus30 family

- Biocompatible

- Biocompatible Clear MED610

- Dental Materials

- Dental TrueDent Materials

- Dental TrueDent-D Materials

- Digital ABS Plus

- DraftGrey

- Elastico Clear/Black

- High Temperature

- PolyJet Support

- Rigur & Durus

- Tango

- ToughONE™

- MED610-DSG

- Transparent

- Vero ContactClear

- Vero Family

- Veroflex

- VeroUltra Opaque

- Vivid Colors

- Stereolithography Materials

- Somos® 9120™

- Somos® BioClear™

- Somos® DMX SL™ 100

- Somos® Element™

- Somos® EvoLVe™ 128

- Somos® GP Plus™ 14122

- Somos® Momentum™

- Somos® NeXt™

- Somos® PerFORM™

- Somos® PerFORM Reflect™

- Somos® ProtoGen™ 18420

- Somos® ProtoTherm™ 12120

- Somos® Taurus™

- Somos® WaterClear® Ultra 10122

- Somos® WaterShed® AF

- Somos® WaterShed® Black

- Somos® WaterShed® XC 11122

- Somos® WaterShed® XC+

J826, J835, J850 & FabriX Kit Support

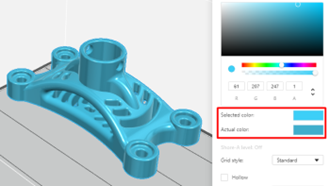

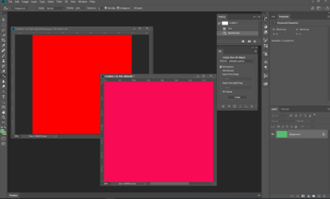

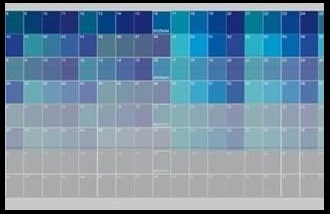

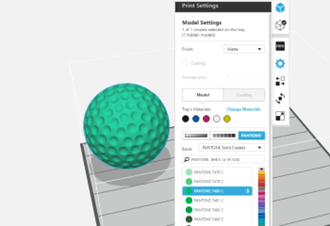

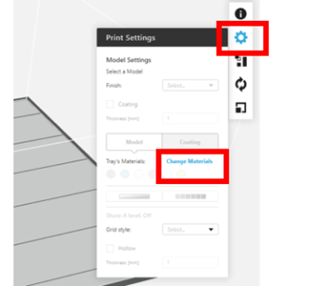

The Stratasys J8 Series 3D printers allow you to streamline and economize the process of producing models from different materials on the same build tray, in the same print job. With the J8 Series 3D printers you can designate colors for parts of a model at the design stage (with CAD software) and save the model as a VRML file, and have the model print with the desired colors.

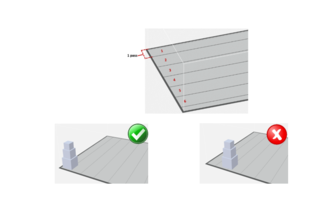

The Stratasys J826 Prime 3D printer has a build area of 255 x 252 x 200 mm (10.0 x 9.9 x 7.8 in). The Stratasys J835 3D printer has a build area of 350 x 350 x 200 mm (13.8 x 13.8 x 7.8 in). The Stratasys J850 Pro/Prime 3D printer has a build area of 490 x 390 x 200 mm (19.3 x 15.35 x 7.9 in).

FabriX™ Innovation Kit: Experiment with Stratasys FabriX™ Innovation Kit and extend your 3D printing capabilities with an advanced set of tools.

FabriX™ Innovation Kit is supported by the J850 Prime Printer.

For 3DFashion Best Practices and Troubleshooting information, go to the Resources page. To find answers to Frequently Asked Questions about 3DFashion, go to the FAQs page.

- 100–120 VAC, 50–60 Hz, 13.5 A, 1 phase

Or

220–240 VAC, 50–60 Hz, 7 A, 1 phase

AC Power Requirements

- Required prior to printer installation.

- Confirm at http://[printer IP address]:80.

- Static IP address.

LAN Requirements

Get a Quote for this Printer.

Buy Stratasys Materials and Service Consumables in Our Online Store

Service Contract Offering

Optimize your 3D printing with a service agreement -

seamless support, minimized downtime.

8:06

GrabCAD Print Features Overview - 3DFashion Technology

3:53

Head Replacement - J7 and J8 Series

Featured Case Studies

Seoul National University Project R - EN PolyJet Case Study

Learn how generative restoration is reimagining Korean cultural heritage at Seoul National University.

Microsoft Xbox Controller Prototyping - EN PolyJet Case Study

Read about how Microsoft is revolutionizing Xbox controller designs with Stratasys PolyJet 3D printing technology.