- PolyJet Legacy Printers

- Alaris30 V1

- Connex260

- Connex350/500

- Eden250

- Eden260

- Eden260V/VS

- Eden330

- Eden350

- Eden350V/500V

- J700 & J720 Dental

- J750/J735

- J750 Digital Anatomy

- Objet24/30 V2 Family

- Objet24/30 V3 Family

- Objet30 V5 Pro & Prime

- Objet260 Connex 1-2-3

- Objet260 Dental & Dental Selection

- Objet350/500 Connex 1-2-3

- Objet1000 Plus

- PolyJet Materials

- Agilus30 family

- Biocompatible

- Biocompatible Clear MED610

- Dental Materials

- Dental TrueDent Materials

- Dental TrueDent-D Materials

- Digital ABS Plus

- DraftGrey

- Elastico Clear/Black

- High Temperature

- PolyJet Support

- Rigur & Durus

- Tango

- ToughONE™

- MED610-DSG

- Transparent

- Vero ContactClear

- Vero Family

- Veroflex

- VeroUltra Opaque

- Vivid Colors

- Stereolithography Materials

- Somos® 9120™

- Somos® BioClear™

- Somos® DMX SL™ 100

- Somos® Element™

- Somos® EvoLVe™ 128

- Somos® GP Plus™ 14122

- Somos® Momentum™

- Somos® NeXt™

- Somos® PerFORM™

- Somos® PerFORM Reflect™

- Somos® ProtoGen™ 18420

- Somos® ProtoTherm™ 12120

- Somos® Taurus™

- Somos® WaterClear® Ultra 10122

- Somos® WaterShed® AF

- Somos® WaterShed® Black

- Somos® WaterShed® XC 11122

- Somos® WaterShed® XC+

3D Printing Case Studies

In this section you can find Case Studies for all Stratasys technologies: FDM, PolyJet, P3 & SAF.

Case Studies illustrates how 3D Printing provided an added value in optimization of the manufacturing process and/or cost reduction for a specific customer.

2:58

EN Mercury Marine FDM Case Study (2m 58s)

3:58

Ogle Models Case Study 2023 - Neo Stereolithography

Featured Case Studies

GrabCAD Shop COVID-19 - Case Study

Read how GrabCAD Shop helped orchestrate the mass production of 100,000 face shields for hospitals & firstline responders at the height of the COVID-19 pandemic.

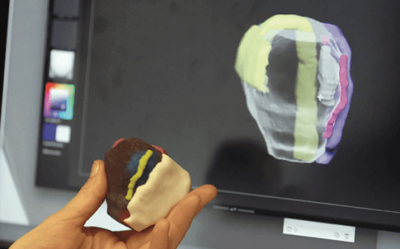

Thinkable Studio - EN PolyJet Case Study

Thinkable Studio develops new products for international businesses in the consumer goods, industrial technology, and medical markets. The use of full CMF capabilities via J55 is enabling the agency to produce prototypes with unrivalled realism.

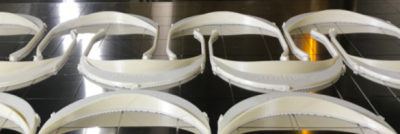

General Motors Conveyor Hangers - EN FDM Use Case

See how General Motors used an F900 printer with FDM Nylon 12CF instead of aluminum to make an Overhead Conveyor Hanger, ultimately reducing downtime and a 32% reduction in weight and an 80% time savings.