- PolyJet Legacy Printers

- Alaris30 V1

- Connex260

- Connex350/500

- Eden250

- Eden260

- Eden260V/VS

- Eden330

- Eden350

- Eden350V/500V

- J700 & J720 Dental

- J750/J735

- J750 Digital Anatomy

- Objet24/30 V2 Family

- Objet24/30 V3 Family

- Objet30 V5 Pro & Prime

- Objet260 Connex 1-2-3

- Objet260 Dental & Dental Selection

- Objet350/500 Connex 1-2-3

- Objet1000 Plus

- PolyJet Materials

- Agilus30 family

- Biocompatible

- Biocompatible Clear MED610

- Dental Materials

- Dental TrueDent Materials

- Dental TrueDent-D Materials

- Digital ABS Plus

- DraftGrey

- Elastico Clear/Black

- High Temperature

- PolyJet Support

- Rigur & Durus

- Tango

- ToughONE™

- MED610-DSG

- Transparent

- Vero ContactClear

- Vero Family

- Veroflex

- VeroUltra Opaque

- Vivid Colors

- Stereolithography Materials

- Somos® 9120™

- Somos® BioClear™

- Somos® DMX SL™ 100

- Somos® Element™

- Somos® EvoLVe™ 128

- Somos® GP Plus™ 14122

- Somos® Momentum™

- Somos® NeXt™

- Somos® PerFORM™

- Somos® PerFORM Reflect™

- Somos® ProtoGen™ 18420

- Somos® ProtoTherm™ 12120

- Somos® Taurus™

- Somos® WaterClear® Ultra 10122

- Somos® WaterShed® AF

- Somos® WaterShed® Black

- Somos® WaterShed® XC 11122

- Somos® WaterShed® XC+

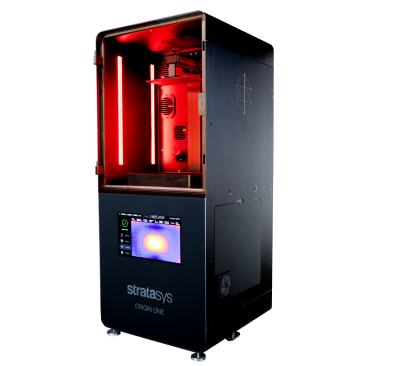

Origin One 3D Printer Support

A transformative 3D printer enabling mass production of end-use parts in a diverse range of high-performance materials. Achieve industry-leading accuracy, consistency, detail and throughput with the Programmable PhotoPolymerization P3™ technology.

The Origin One printer has a build size of 192 x 108 x 370 mm (7.5 x 4.25 x 14.5 in).

- 90 - 264 VAC

- 50 - 60 HZ, 700 W 1 phase

AC Power Requirements

- Ethernet

LAN Requirements

Get a Quote for this Printer.

Buy Stratasys Materials and Service Consumables in Our Online Store

Service Contract Offering

Optimize your 3D printing with a service agreement -

seamless support, minimized downtime.

3:21

Using the Tray Pour Jig - Origin One

4:50

Post-Processing - Curing - Origin One

Featured Case Studies

NISMO Racing - EN P3 Case Study

Discover how Stratasys Origin One flexible production capability produces end-use parts for Nissan’s Super GT racing team.

ECCO Footwear Mold - EN Case study

Learn how ECCO, Henkel Loctite and the Origin One team collaborated to create molds for ECCO's DIP shoe manufacturing process.