Printers

- PolyJet Legacy Printers

- Alaris30 V1

- Connex260

- Connex350/500

- Eden250

- Eden260

- Eden260V/VS

- Eden330

- Eden350

- Eden350V/500V

- J700 & J720 Dental

- J750/J735

- J750 Digital Anatomy

- Objet24/30 V2 Family

- Objet24/30 V3 Family

- Objet30 V5 Pro & Prime

- Objet260 Connex 1-2-3

- Objet260 Dental & Dental Selection

- Objet350/500 Connex 1-2-3

- Objet1000 Plus

Materials

- PolyJet Materials

- Agilus30 family

- Biocompatible

- Biocompatible Clear MED610

- Dental Materials

- Dental TrueDent Materials

- Dental TrueDent-D Materials

- Digital ABS Plus

- DraftGrey

- Elastico Clear/Black

- High Temperature

- PolyJet Support

- Rigur & Durus

- Tango

- ToughONE™

- MED610-DSG

- Transparent

- Vero ContactClear

- Vero Family

- Veroflex

- VeroUltra Opaque

- Vivid Colors

- Stereolithography Materials

- Somos® 9120™

- Somos® BioClear™

- Somos® DMX SL™ 100

- Somos® Element™

- Somos® EvoLVe™ 128

- Somos® GP Plus™ 14122

- Somos® Momentum™

- Somos® NeXt™

- Somos® PerFORM™

- Somos® PerFORM Reflect™

- Somos® ProtoGen™ 18420

- Somos® ProtoTherm™ 12120

- Somos® Taurus™

- Somos® WaterClear® Ultra 10122

- Somos® WaterShed® AF

- Somos® WaterShed® Black

- Somos® WaterShed® XC 11122

- Somos® WaterShed® XC+

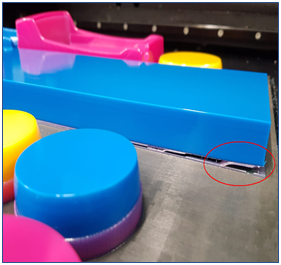

Curling

3D Printing Curling

Sometime, parts may curve upwards and detach from the build tray. This can happen with certain materials or printing processes for various reasons.

Possible Causes and Solutions

Internal stress may cause parts to curve upwards and detach from the tray. Below you can find some recommended solutions.

Change Part Orientation

- Try placing the longest part of the model to on the Y axis or on a slant. This extends print time.

- Try placing a small model in the lower right corner of the tray. This will result in a longer print time for each slice.

Change the Model Material

Try changing a rigid material to a VeroFlex or a digital material of Vero and flex material, as VeroFlex is less sensitive to curling.

Preventive measures: Same as above.

Change the Settings

- A matte surface finish may reduce the UV exposure to the top layers of a print for certain geometries.

- In the Tray Settings dialog box, select the check box Minimum pause between slices...

It is recommended to start by changing the delay time to 40 seconds. If it helps prevent the curling, you can try reducing the delay time and checking the results.

Preventive measures: Same as above.

Check the UV Intensity

Calibrate the UV lamp and contact your Stratasys service provider.

Preventive measures: Same as above.