プリンタ

- PolyJet プリンタ(旧タイプ)

- Alaris30 V1

- Connex260

- Connex350/500

- Eden250

- Eden260

- Eden260V/VS

- Eden330

- Eden350

- Eden350V/500V

- J700 & J720 Dental

- J750/J735

- J750 Digital Anatomy

- Objet24/30 V2ファミリー

- Objet24/30 V3ファミリー

- Objet30 V5 Pro & Prime

- Objet260 Connex 1-2-3

- Objet260 Dental/Dental Selection

- Objet350/500 Connex 1-2-3

- Objet1000 Plus

材料

- Stereolithography Materials

- Somos® 9120™

- Somos® BioClear™

- Somos® DMX SL™ 100

- Somos® Element™

- Somos® EvoLVe™ 128

- Somos® GP Plus™ 14122

- Somos® Momentum™

- Somos® NeXt™

- Somos® PerFORM™

- Somos® PerFORM Reflect™

- Somos® ProtoGen™ 18420

- Somos® ProtoTherm™ 12120

- Somos® Taurus™

- Somos® WaterClear® Ultra 10122

- Somos® WaterShed® AF

- Somos® WaterShed® Black

- Somos® WaterShed® XC 11122

- ソモス®・ウォーターシェッド® XC+

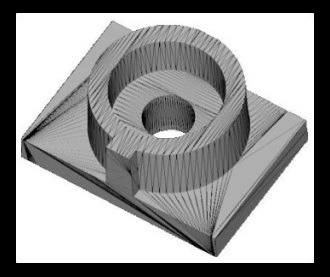

J55 Prime

Stratasys J55 Prime 3Dプリンタを使用すると、同一の造形ジョブ内で、異なる材料でできたモデルを同じ造形トレイ上で製作するプロセスを合理化し、コストを削減できます。J55 Prime 3Dプリンタでは、設計段階で(CADソフトウェアを使用して)モデルのパーツに色を指定し、モデルをVRMLファイルとして保存して、目的の色でモデルを造形できます。

J55 Prime 3Dプリンタの造形サイズは、140 x 200 x 190 mm(5.5 x 7.8 x 7.5インチ)です。

- 50/60 Hz

- 100~240 VAC

- 10 A

- 650 W

AC電源要件

- プリンタを設置する前に必要となります。

- http://[プリンタのIPアドレス]:80でご確認ください。

- 静的IPアドレス。

LAN要件

- デザインプロトタイプ

- 色

用途

このプリンタの見積りを請求する

ストラタシスの材料やサービス消耗品のご購入はオンラインストアからどうぞ

1:38

3D Printers Pattern Test J5 Series

1:22

3D Printers Wiper Replacement J5 Series

注目の活用事例

ジョンマウリエロ氏によるサングラスの試作品 - EN PolyJetケーススタディ

ジョンマウリエロ氏が設計プロセスの課題を克服するにあたって、PolyJet 3Dプリンタ技術がどのように役立ったかをご覧ください。

SEONG YUN TECH - EN PolyJet Case Study

SEONG YUN TECH社は、半永久アートメイクの機器と針を専門とするメーカーおよび販売業者です。

J55 Primeプリンタに切り替えることで、同社は製造プロセスにおける時間とコストを最適化しました。その方法をご確認ください。

GrabCADチュートリアル

|