- PolyJet 레거시 프린터

- Alaris30 V1

- Connex260

- Connex350/500

- Eden250

- Eden260

- Eden260V/VS

- Eden330

- Eden350

- Eden350V/500V

- J700 & J720 Dental

- J750/J735

- J750 Digital Anatomy

- Objet24/30 V2 제품군

- Objet24/30 V3 제품군

- Objet30 V5 Pro & Prime

- Objet260 Connex 1-2-3

- Objet260 Dental/Dental Selection

- Objet350/500 Connex 1-2-3

- Objet1000 Plus

- 광조형 재료

- Somos® 9120™

- Somos® BioClear™

- Somos® DMX SL™ 100

- Somos® Element™

- Somos® EvoLVe™ 128

- Somos® GP Plus™ 14122

- Somos® Momentum™

- Somos® NeXt™

- Somos® PerFORM™

- Somos® PerFORM Reflect™

- Somos® ProtoGen™ 18420

- Somos® ProtoTherm™ 12120

- Somos® Taurus™

- Somos® WaterClear® Ultra 10122

- Somos® WaterShed® AF

- Somos® WaterShed® Black

- Somos® WaterShed® XC 11122

- Somos® WaterShed® XC+

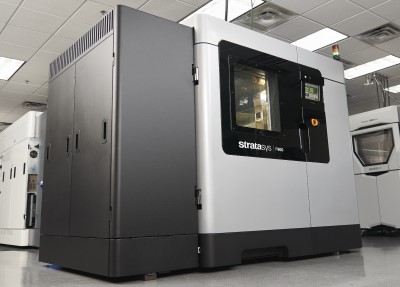

Fortus 900mc/F900

Stratasys Fortus 900mc/F900 3D 프린팅 시스템은 혁신적인 최신 기술을 결합하여 CAD 설계에서 정밀한 프로토타입을 제공합니다. Stratasys의 용융 적층 모델링(FDM) 기술은 필드 테스트 양식, 맞춤 및 함수에 사용할 수 있는 내부 기능을 포함한 프로토타입 부품을 제공합니다.

Stratasys Fortus 900mc/F900 3D 프린팅 시스템은 진공 조형판이 있으며 두 개의 빌드 시트 크기로 사용하는 데 적합합니다. 작은 시트는 16인치(40.6cm) X 18.5인치(47.0cm) X 0.02인치(0.05cm)(두께), 큰 시트는 26인치(66.0cm) X 38인치(96.5cm) X 0.02인치(0.05cm)(두께)입니다. 조형 사이즈는 36인치(91.4cm)(폭) X 36인치(91.4cm)(높이) X 24인치(60.96cm)(깊이)입니다. 이 프린터의 재료 베이는 모델용 두 개, 서포트용 두 개로 총 네 개가 있습니다.

- 50Hz 또는 60Hz

- 230VAC

- 40A 회로

- 3상 모두에서 전체 부하 전류 34A

AC 전원 요구 사항

- 통신 및 파일 전송 기능에 필요합니다.

- Category 5 이상

- 10/100 Base T 이더넷, RJ45 커넥터.

LAN 요구 사항

이 프린터의 견적을 받아보십시오.

당사 온라인 스토어에서 Stratasys 원료 및 서비스 소모품을 구매하십시오.

1:27

As Needed Maintenance - F900

5:34

How to Use TrueRefill on Fortus 450mc and F900mc

주요 사례 연구

General Motors Hemming - EN FDM Use Case

General Motors(GM)는 전기 자동차와 자율 주행차 기술을 포함한 운송 혁신 기술 개발에 있어 세계적인 선도 기업입니다. 미시간주 디트로이트에 본사를 둔 GM은 6개 대륙에 164,000명의 직원을 두고 서비스를 제공합니다.

General Motors가 3D 프린팅을 사용하여 비용을 절감한 방법에 대해 알아보십시오.

IDEC and Wehl - EN FDM Case Study

항공우주 사례 연구: IDEC는 항공우주 산업을 위한 복합 솔루션의 선도적 스페인 공급업체로서 고객의 설계 및 제작 요구를 충족시킵니다. 이 회사는 선도적인 제조 용역 회사인 Wehl & Partner의 지원으로 기존 복합 몰딩의 시간, 비용 및 자재 낭비를 줄임으로써 경쟁력을 높이는 프로젝트에 착수했습니다.