打印机

- PolyJet Legacy 打印机

- Alaris30 V1

- Connex260

- Connex350/500

- Eden250

- Eden260

- Eden260V/VS

- Eden330

- Eden350

- Eden350V/500V

- J700 和 J720 Dental

- J750/J735

- J750 Digital Anatomy

- Objet24/30 V2 系列

- Objet24/30 V3 系列

- Objet30 V5 Pro 和 Prime

- Objet260 Connex 1-2-3

- Objet260 Dental/Dental Selection

- Objet350/500 Connex 1-2-3

- Objet1000 Plus

材料

- 立体光刻材料

- Somos® 9120™

- Somos® BioClear™

- Somos® DMX SL™ 100

- Somos® Element™

- Somos® EvoLVe™ 128

- Somos® GP Plus™ 14122

- Somos® Momentum™

- Somos® NeXt™

- Somos® PerFORM™

- Somos® PerFORM Reflect™

- Somos® ProtoGen™ 18420

- Somos® ProtoTherm™ 12120

- Somos® Taurus™

- Somos® WaterClear® Ultra 10122

- Somos® WaterShed® AF

- Somos® WaterShed® Black

- Somos® WaterShed® XC 11122

- 索莫斯® WaterShed® XC+

Übersetzte Resourcen

Auf dieser Seite finden Sie eine umfassende Auflistung aller verfügbaren Ressourcen in deutscher Sprache.

Nachfolgend finden Sie Beispiele für Assets in diesem Abschnitt:

- Fallstudie:Veranschaulicht, wie der 3D-Druck einen Mehrwert für einen bestimmten Kunden darstellte.

- Benutzerhandbuch:Beschreibt die Betriebsanleitungen, die Wartung und die Fehlerbehebung der Produkte.

- Leitfaden zur Standortvorbereitung:Beschreibt die Standortanforderungen für die Installation des Produkts.

2:29

DE - F120 Anatomy HD 149s

1:37

德语 - J850 产品视频

Ausgewählte Fallstudien

Marchesini - DE FDM Case Study

Marchesini Group S.p.A. ist ein führender italienischer Hersteller automatischer Verpackungsmaschinen und ein bewährter Zulieferer einiger der größten Unternehmen der Pharma-, Kosmetik- und Lebensmittelindustrie.Die Produktionsstätten von Marchesini Group sind spezialisiert auf das Design, die Entwicklung und die Fertigung besonderer Verpackungslinien.

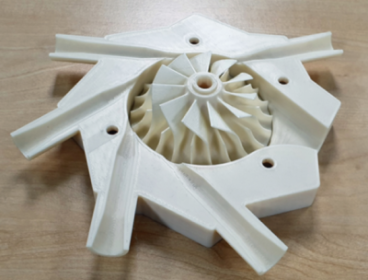

JohnCrane - DE FDM Case Study

John Crane transformiert Ersatz von Werkzeug und Metallteilen durch Additive Fertigung.

John Crane ist ein vor über 100 Jahren gegründetes und weltweit führendes Unternehmen von Lösungen für Rotationsanlagen.