1 Service and Support

This chapter provides information on service and support for the F123 Series as well as safety information and safety label locations.

If you have a problem with your printer that is not covered in this guide, please contact Stratasys Customer Support. Contact information is available from the Stratasys website at: http://www.stratasys.com/customer-support/contact-customer-support.

When calling in for service, always have your printer’s software version (see “Software Version” (page 32)) and hardware serial number available (see “Identifying Your Printer” (page 7)). You may also need access to GrabCAD Print to provide a configuration file from your hardware (see “Exporting System Configuration (.CFG) File” (page 6)).

If you have a software problem that is not covered in this guide, please contact Stratasys Customer Support. Contact information is available from the Stratasys website at: http://www.stratasys.com/customer-support/contact-customer-support.

When calling in for service, always have your printer’s software version (see “Software Version” (page 32)) and printer serial number available (see “Identifying Your Printer” (page 7)). You may also need access to GrabCAD Print to provide a configuration file from your hardware (see “Exporting System Configuration (.CFG) File” (page 6)).

The following basic safety tips are given to ensure safe installation, operation, and maintenance of Stratasys equipment and are not to be considered as comprehensive on matters of safety. The F123 Series printers are designed to be safe and reliable rapid prototyping printers. Access to areas of the printer are potentially dangerous.

Stratasys recommends that all services be performed by qualified personnel. All personnel working on or around the printer should be knowledgeable of what the following hazard classifications mean throughout this guide.

•Warnings and Cautions precede the paragraph to which they pertain.

|

|

Warning: Indicates a potentially hazardous situation which, if not avoided, may result in injury or death. |

|

|

Caution: Indicates a situation which, if not avoided, could result in damage to equipment. |

•Notes follow the relative paragraph.

|

|

Indicates additional information relative to the current topic. |

|

|

Always read and adhere to safety statements, and be aware of the following safety signs when you see them on the printer. |

Stratasys makes every effort to ensure that our printers are safe and reliable at all times. However, there will be times when you must access areas of the printer where potentially high voltages, hot temperatures, and/or moving mechanical components could cause severe injury.

|

Warning Symbols |

Meaning |

Location |

Comments |

|---|---|---|---|

|

|

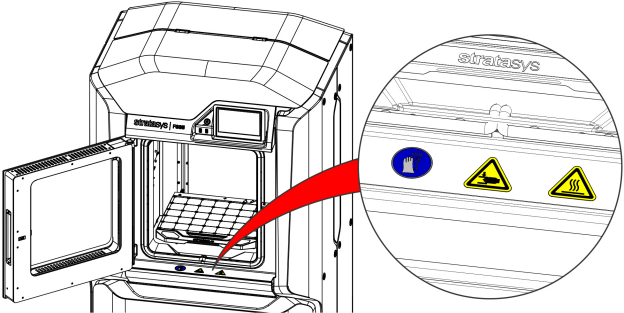

Hot surface |

Oven entrance |

Risk of burns. Do not touch this surface after printing. |

|

|

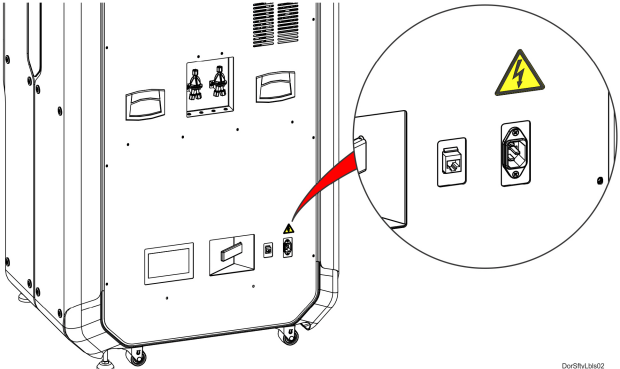

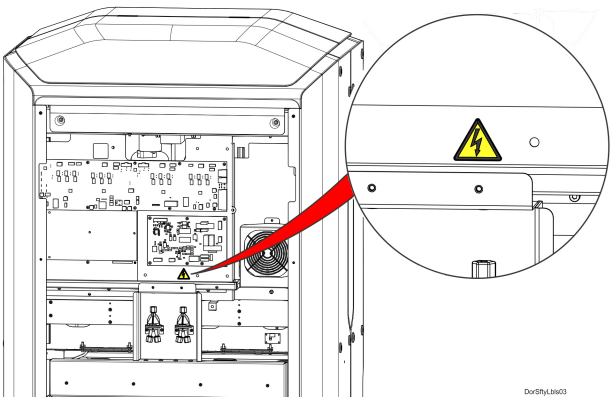

High voltage |

Electrical panel, near the power-supply enclosures |

Risk of electric shock. |

|

Gloves |

Oven entrance |

Safety gloves approved for high temperatures must be worn in locations where this symbol is displayed. |

|

Moving parts |

Oven entrance |

Risk of injury from moving parts. |

Product Safety Label Locations

Figure 1: Oven safety label locations

Figure 2: Rear panel safety label locations

Figure 3: Electrical panel safety label locations

The following components and areas of the printer are highlighted as potential safety hazards that may cause system failure or reliability problems if proper safety procedures are not followed.

|

|

Warning: Hot Surfaces. Always wear safety gloves and long sleeves when working inside the oven. Components are hot. |

|

|

Opening the oven door shuts the oven heaters off. |

|

|

Warning: Moving Parts. Never wear a tie, loose clothing or dangling jewelry when working around moving components of the printer. Beneath the top cover of the printer is the gantry. This area houses the mechanical drive components of the X and Y axes. Use extreme caution whenever accessing this area of the printer. |

|

|

The printer’s servo motors are disabled when the oven door and/or top cover are open. The XY pinch hazard between the timing belts and pulleys is minimized by locking the oven door and top cover while building and disabling the motors when the oven door and top cover are open. The oven door and top cover automatically lock when the printer is building and cannot be opened while the printer is building. You cannot start a build if the oven door or top cover are open. |

Interlock switches are used to communicate the status of the oven door and the top cover to the printer. For safety reasons, the oven door and top cover must be closed before the X, Y, and Z motors will operate.

Abide by these general safety practices when working with this printer.

|

|

Warning: High Voltage. High voltage is present in the printer. |

|

|

Warning: Falling Hazard. Only use an OSHA or CE approved step stool when accessing the area under the top cover of the printer. |

|

|

Warning: Hot Surfaces. Always wear safety gloves and long sleeves when working inside the oven. Components are hot. |

•The F123 Series printer is for indoor use only.

•Air quality conditions with excessive solid particulates (conductive or non-conductive) may result in system damage.

•Air quality conditions in which airborne oils are allowed to accumulate on or within the printer can damage the plastic components.

•System operating temperature shall be in the range of 59°F to 86°F (15°C to 30°C), with relative humidity range of 30% to 70% non-condensing.

•System storage temperature shall be in the range of 32°F to 95°F (0°C to 35°C), with relative humidity range of 20% to 90% non-condensing.

•Altitude shall not exceed 6561.68 feet (2000 m).

•Material storage shall be in the range of 55°F to 86°F (13°C to 30°C), with relative humidity less than 70%.

•Noise emission (acoustic):

•<32dBA when idle

•<46dBA when building