Replacing the Waste-Pump Tubes

The tubes that pump waste material from the roller waste collector and the purge unit should be replaced after 1000 hours of use. After this time, the printer software sends a maintenance alert to display on the printer interface screen.

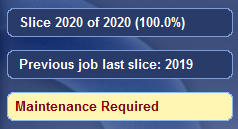

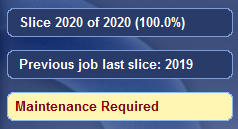

You can check when the pump tubes need to be replaced in the Maintenance Counters interface.

To open the Maintenance Counters interface:

|

➢

|

Click on the "Maintenance Required" indicator. |

or—

|

➢

|

From the Options menu, select Maintenance Counters. |

When the Maintenance Counters screen opens, scroll down to the General Pumps section.

The waste-pump tubes that require replacing are displayed in red.

Note: If the check box on the right is selected, the "Maintenance Required" indicator appears when that task is due.

To replace pump tubes, you replace the entire pump "cassette" in the printer. Replacement cassettes are supplied in the printer Start-up Kit. Additional cassettes can be ordered from your Stratasys service provider.

To replace the waste pump tubes:

|

•

|

disposable cleaning gloves

|

|

•

|

a supplied cleaning cloth or equivalent

(for cleaning the material that spills while replacing the tubes) |

|

•

|

disposable cup (for catching material from the tubes when the fittings are disconnected) |

|

2.

|

Make sure that the printer is in Idle mode. |

Note: The printer enters Idle mode about 16 minutes after printing stops. To force the printer into Idle mode, close the printer application: From the File menu, click Exit.

|

3.

|

Using an 8-mm hex (Allen) key, open the two latches that secure the left printer panel (as you face the printer). |

|

4.

|

Open the panel and disconnect the ground (earth) wire. |

|

6.

|

Identify the waste pump that requires tube replacement. |

|

7.

|

Put on protective gloves and eye wear. |

Uncured printing material might cause skin and eye irritation. Use disposable cleaning gloves to protect your hands and protective eye wear to protect your eyes.

|

8.

|

Disconnect the fittings: |

a. Unscrew the fittings that connect each waste-pump tube.

b. Separate the tubes and put them into the disposable cup to catch material that spills.

|

9.

|

Remove the part of the fitting remaining on the pump tube, and save it. |

|

10.

|

Rotate the white restraining clip to release the pump. |

|

11.

|

When the tubes on both sides of the pump are disconnected, rotate the pump "cassette" counter-clockwise and remove it. |

|

12.

|

Holding a new pump cassette with one hand, rotate the rotor. |

This ensures that the pump functions properly after a long storage period.

|

13.

|

Attach the new pump cassette to the printer. |

Fit the cassette into the slots in the housing, and turn clockwise to working position.

|

14.

|

Rotate the white restraining clip to secure the pump. |

|

15.

|

Remove the clamp from the tube that is directed to the waste container (pump outlet). |

|

16.

|

Connect the tubes to the new pump cassette. |

|

17.

|

Use the cleaning cloth to wipe the spilled material. |

|

18.

|

Perform the Pattern Test and make sure the pump cassette operates properly. See Pattern Test. |

|

19.

|

If necessary, replace the pump cassette on the other waste pump. |

|

20.

|

Attach the panel to the printer. |

Make sure to reconnect the ground wire to the printer panel.

|

21.

|

Open the Maintenance Counters screen, scroll down to the General Pumps section, and click Reset for the relevant counter(s). |